Gay Frères was founded in 1835 by Jean-Pierre Gay and Gaspard Tissot . At first, the company made pocket watch chains for pocket watches, but also jewelry necklaces and more. It has also manufactured PP, VC, AP Royal Oak, Breitling bullet belts and other brand styles.

Breitling bullet belt

Starting from the 1930s and 1940s, all Rolex watch straps were basically manufactured by Gay Frères. And it was acquired by Rolex in 1998. Rolex is very similar to Apple. Apple also often acquires companies that develop technology or OEM for it. Become an indispensable subsidiary of its own industrial supply chain

Oyster straps through the ages

As shown in the picture, the first generation Oyster strap is similar to the Breitling bullet belt. The first generation Oyster strap is mainly used on bubble backs and chronographs. Patented in 1947. The design and construction of the original Oyster strap remained almost unchanged for 15 years after its introduction, but it underwent a major change in 1952. The first generation Oyster strap had straight lugs, which were changed to curved lugs in 1952.

As shown in the picture above, straight ear sills are suitable for mass production. Those with different logos can be used by different watch models and manufacturers. The biggest problem is that it affects the appearance and use. You can see that the straight sills and the watch body are not consistent. match. Later, Gay Frères replaced the straight ear canals with curved ones to better match the watch body, which is more durable and more beautiful. (Patent No. 303005)

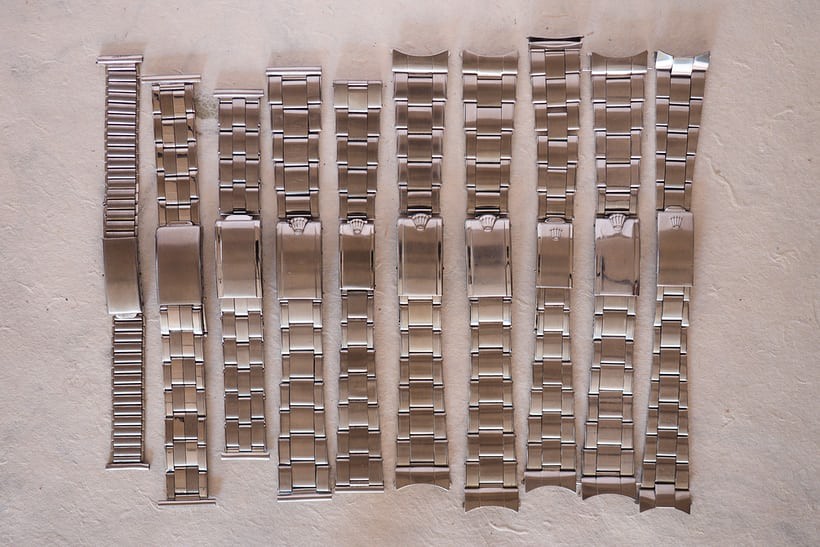

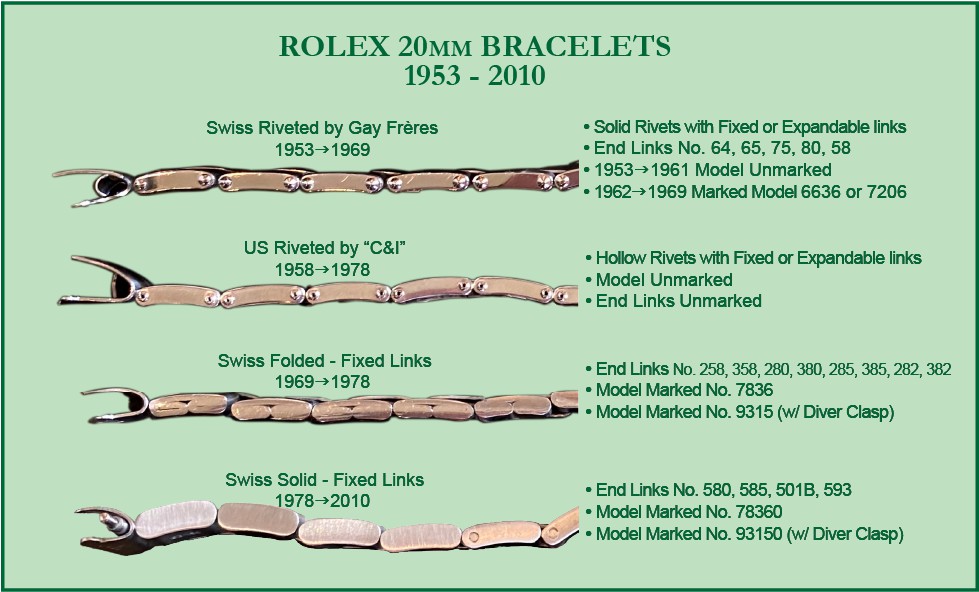

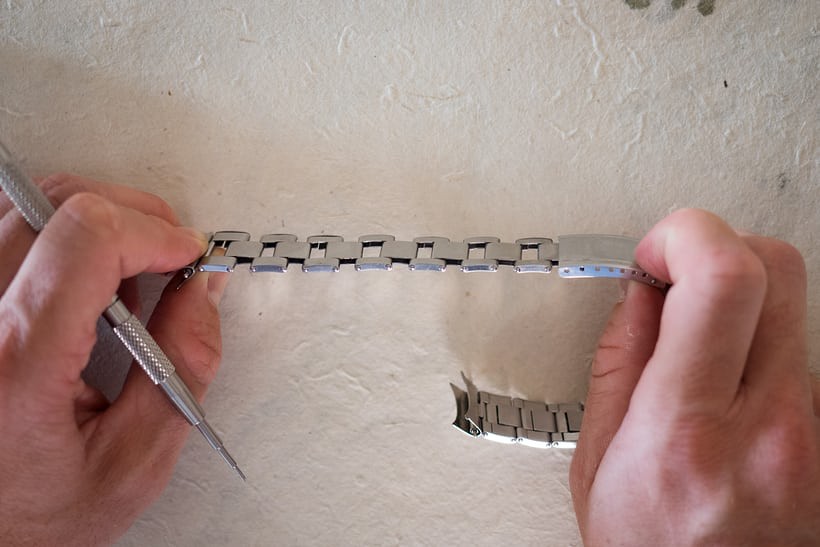

Since the early 1950s, the Rolex Oyster watch has continued to evolve, and so have the straps to match. Oyster positioning is a tool watch, the most durable. Therefore, the Oyster strap must become more durable and reliable. The most straightforward and efficient method is weight incrementing. The change can be seen very quickly as shown in the image above. The original version was what we call a rivet strap. All hollow links are fixed with rivets. The entire weight is very light, and dirt can easily accumulate between the links. After improvement, the core knot replaced the hollow knot. The second version is called the core strap (wrapped steel, folded steel, coiled steel). Looking at the side of the picture, each link is made of multiple folded metal blocks, making it heavier and stronger. Another change was that solid replaced the rolled core, and the third version was called solid strap. The third generation is closer to today's version.

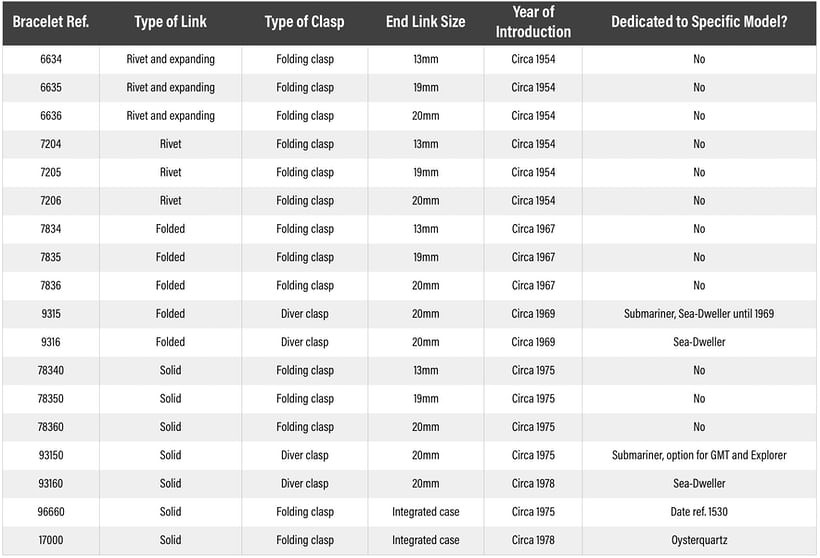

Looking at any generation of Rolex straps , each Oyster generation has a specific reference number, usually found on the lugs of the strap, that not only indicates the generation it belongs to, but also its size. The rivet watchbands made in Switzerland will have codes on the ear canals, but those made in other countries basically do not.

Rolex also commissions watch straps from manufacturers outside Switzerland to help reduce tariffs on imported watches for sale in the United States, Britain and Mexico. Marked "C&I" or "Hecho en Mexico" on the buttons. The most famous manufacturer, C&I is based in the United States and produced a large number of OEM Rolex cousins for about 20 years starting in 1959. The hollow rivets on these straps are thinner than their Swiss-made counterparts, and the steel gauges are lighter and poorer. Another drawback of the American-made bracelet is that the ear canals are not coded and become very loose after being used for a long time.

Expanding links

Expanding links have large gaps

The first generation rivet watch strap also provides two structures, one is our common one. There is also Expanding links, (such as 6634/6635/6636 models). Expanding links soon proved to be less durable than traditional standard fixed links and were phased out.

The second generation of winding straps appeared in the late 1960s, such as models 7834/7835/7836, and began to be made according to the case to fit the earpieces better. Earband encoding allows people to immediately know what the matching watch body is. The rolled core and solid strap lugs have a three-digit code.

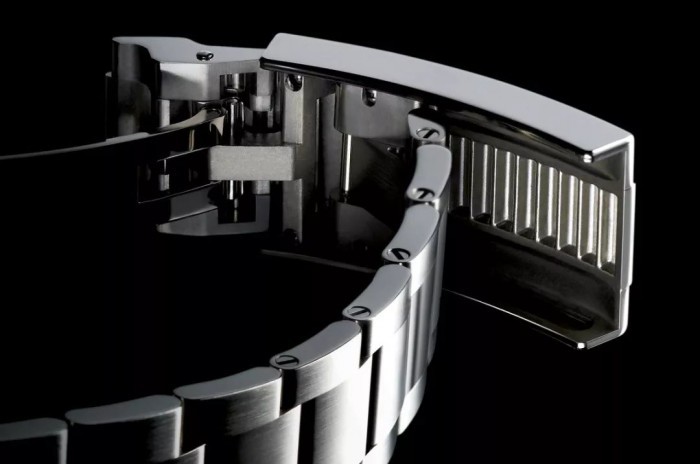

traditional press buckle

additional buckle

Another important evolution is the clasp. While the push-to-fold clasp proved to be effective and simple, when a strong impact is applied, the push-to-fold opens easily, adding to the uncertainty. So the Sub mariner and Sea-Dweller used a patented clasp design in 1969 that added an additional fixed buckle to the basic push-to-fold mechanism and also concealed a built-in extension system. Today's Submariner series and Deepsea series are equipped with Oyster straps with Glidelock.

Glidelock